Bysoft 7 solidworks software download#

Bysoft 7 Software Download Plan and Monitor Manufacturing Processes Bysoft 7 Maintenance Portal This ensures safety, saves even more time and material, and shortens job throughput times. Furthermore, BySoft 7 simulates the bending sequence and displays possible collisions automatically. Bending sequence, backgauge position, and tool plan are detected automatically so that the bending process can start more quickly. With BySoft 7, you can create perfect bending programs. What’s more, BySoft 7 optimizes your cutting processes and automatically selects each optimal cutting technology. To do this, BySoft 7 has countless functions, for example, various nesting processes. Create Cutting PlansīySoft 7 automatically ensures that sheet metal, tubes, and profiles are used completely and nests as many parts as technically possible. Thus, you quickly and confidently achieve correct 3D models of the parts to be manufactured. BySoft 7 provides exactly those tools you need for a specific situation, communicates a clear idea of the immediate status of the model, and is intuitive to use.

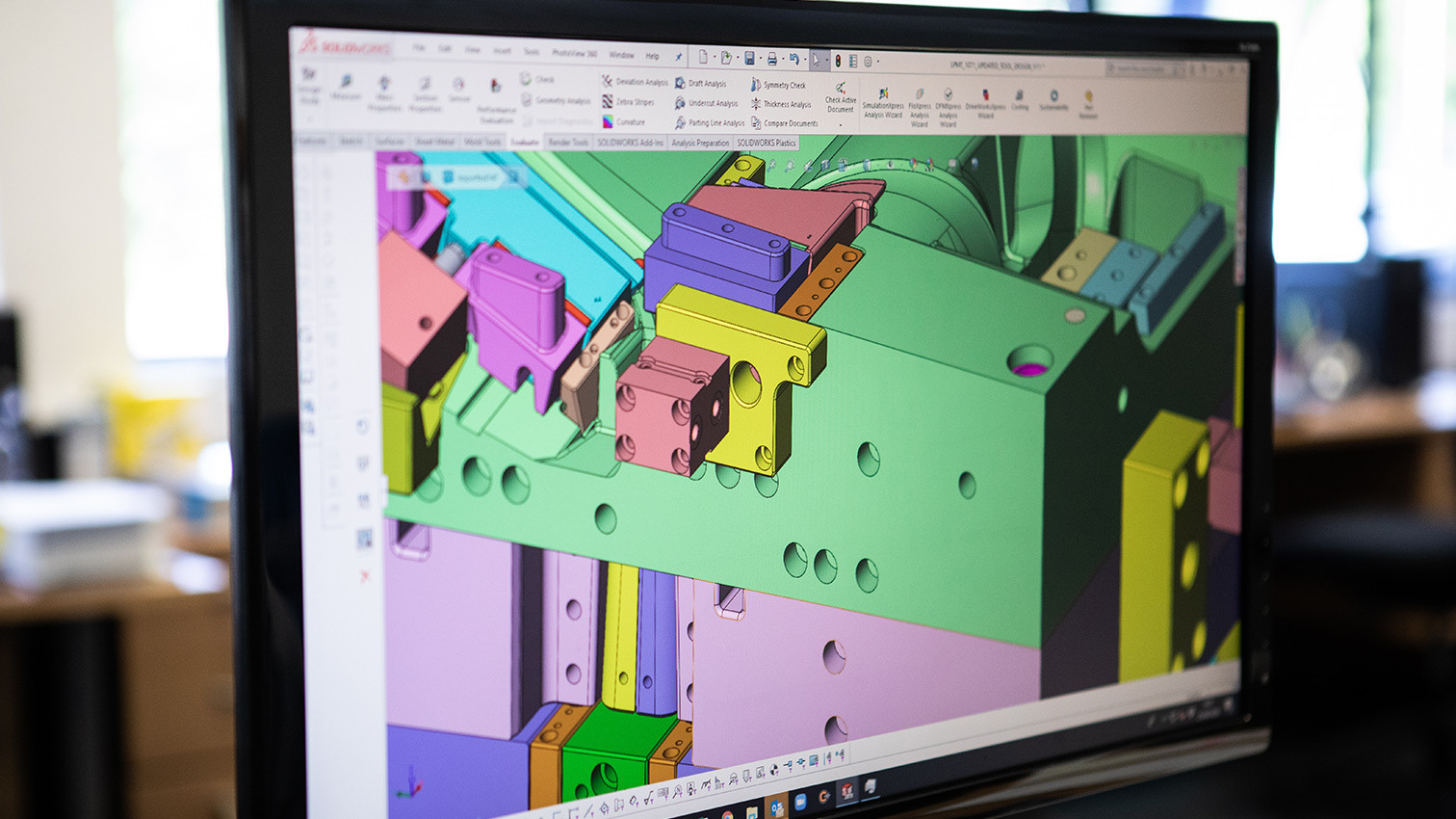

Bystronic Bysoft 7 is new software for Bystronic Lasser Machinas work with solidworks amazing software if need solution contact us.īySoft 7 supports your parts construction with powerful 3D-CAD, widely distributed across the world. Moreover, Plant Manager compiles all relevant machine and production data and makes it continuously available to the operator, providing maximum transparency for both sheet and tube processing.Bystronic Bysoft 7 Test With FlexNet Dongle & License. Plant Manager is a unique operational tool that both plans and monitors manufacturing processes, including all laser and waterjet cutting operations. Optimal cutting plans and bending programs can be generated at the push of a button, with the correct cutting technology automatically set and the bending process is automatically simulated and monitored.īySoft 7 consists of four modules: Sheet Processing, Tube Processing, Bending, and Plant Manager. All operations take place automatically, on the basis of highly reliable data. Secondly, BySoft 7 simplifies processes within the factory with advanced capabilities for nesting parts, creating cutting plans, generating bending programs, simulating bending sequences, and more. First, BySoft 7 employs a highly intuitively structure that enables first-time users to begin working with the software quickly and easily. Among the extensive list of other innovative features are optimized common cut, pre-piercing of selected contours, and automatic scanning.īySoft 7 lives up to its ‘Make it easy’ claim in two ways. Spread nesting increases the distance between nested parts for improved process reliability, while compressed nesting minimizes the safety distance to increase the number of parts per sheet and minimize wasted material. Operators have the ability to choose either spread or compressed nesting. On the CAM side, BySoft 7 introduces a variety of innovations that improve and simplify the manufacturing process. Users can quickly and easily design custom parts, and input existing drawing and models for editing and processing. We market BySoft 7 with the slogan ‘ Make it easy’, and users will find that it delivers fully on this promise.”īySoft 7 incorporates the latest version of SolidWorks, one of the industry’s most popular and respected 2D and 3D CAD packages. Rather, it is a completely new generation of design and manufacturing software generation, with a wide range of new functions that offer a host of possibilities.

Aubin, president of Bystronic Inc., “BySoft 7 is not simply an update. High performance software is fundamental to modern sheet metal processing.īySoft 7 is a robust CAD/CAM software package that supports both 2D and 3D CAD and provides the user with an extensive array of process scheduling and monitoring functions.

0 kommentar(er)

0 kommentar(er)